Custom Camshafts Manufacturers: Revolutionizing Diesel Engine Performance

In the competitive landscape of diesel engine parts, custom camshafts manufacturers play a vital role in optimizing engine performance and efficiency. By focusing on precision engineering and tailored solutions, these innovative manufacturers have become indispensable allies for both manufacturers and end-users of diesel engine components.

Understanding Custom Camshafts

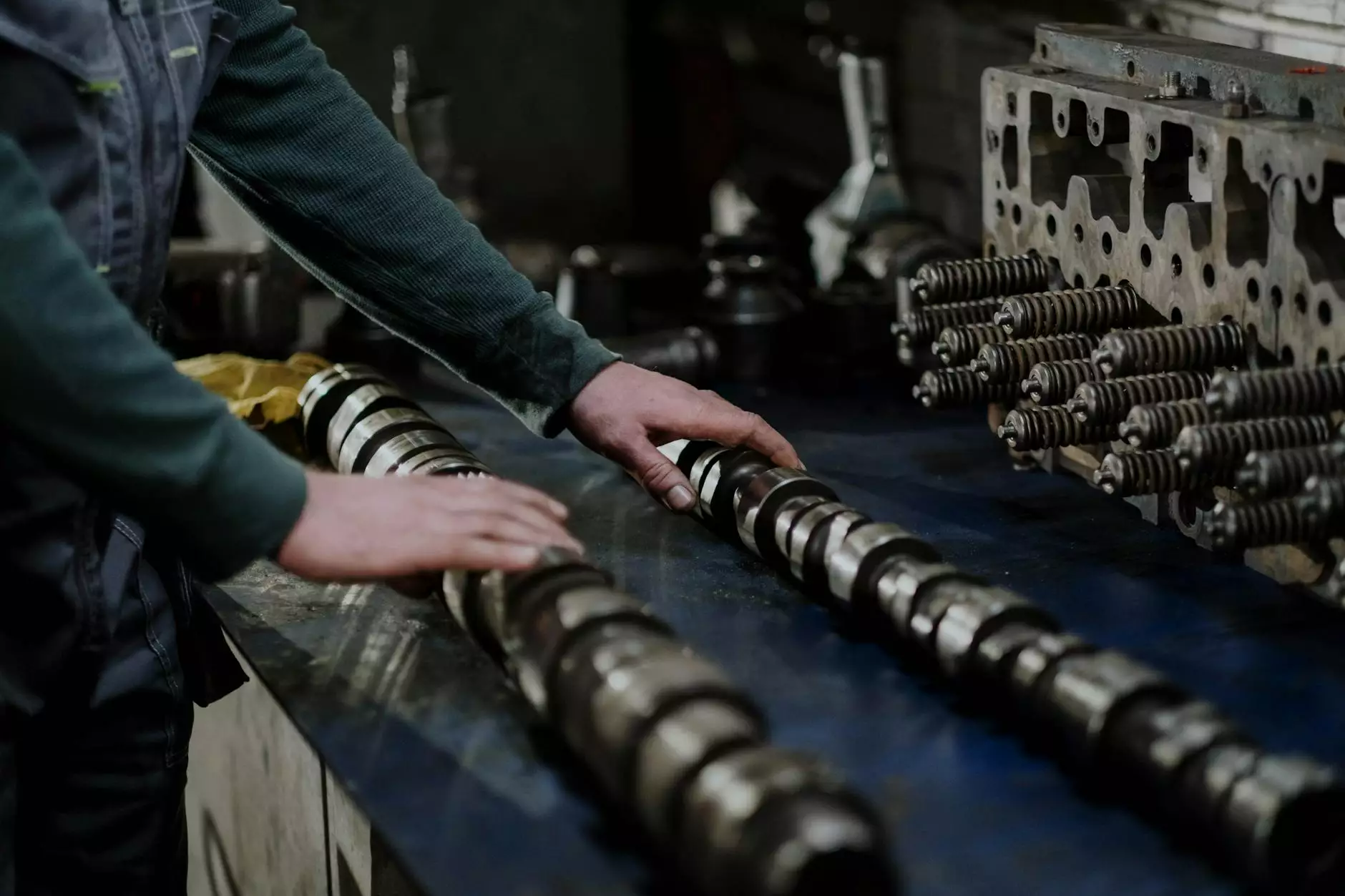

A camshaft is a crucial component in any internal combustion engine, responsible for opening and closing the intake and exhaust valves at the right intervals. The configuration of a camshaft directly affects engine timing, power output, and efficiency. Custom camshafts are specifically designed to meet the unique requirements of various diesel engines, providing an opportunity to enhance performance beyond standard specifications.

The Importance of Quality in Diesel Engine Parts

When it comes to diesel engines, the quality of parts is paramount. High-quality components lead to better performance, increased longevity, and reduced operational costs. Custom camshafts manufacturers ensure that every camshaft is precision-engineered, usually from high-grade materials that can withstand the rigors of diesel engine operation.

Why Choose Custom Camshafts?

- Enhanced Performance: Custom camshafts are designed to optimize the performance characteristics of an engine, allowing for more power and torque.

- Efficiency Boost: Tailored designs can lead to better fuel efficiency, reducing overall operational costs.

- Longevity: Quality materials and precise engineering contribute to a longer lifespan of engine components.

- Exact Fit: Custom options ensure an exact fit for various engine types, minimizing the risk of installation issues.

- Performance Tuning: Manufacturers can adjust the burn characteristics of the engine, enabling tuning for specific performance needs.

How Custom Camshafts Are Made

The process of manufacturing custom camshafts involves several key steps:

1. Design and Engineering

Custom camshafts begin with a design phase where engineers utilize advanced software to simulate and plan the camshaft's specifications. This stage assesses the desired objectives, including performance targets, operating conditions, and compatibility with the diesel engine's existing setup.

2. Material Selection

Quality camshafts require robust materials that can withstand high stress and temperature variations typical of diesel engines. Common materials include:

- Carbon steel

- Alloy steel

- Billet materials

3. Precision Machining

After selecting the materials, the camshaft undergoes precision machining. This step includes:

- Turning and milling the cam profile

- Drilling and grinding journals

- Surface treatment processes to enhance durability

4. Quality Control

Each custom camshaft must pass rigorous quality control checks to ensure it meets the design specifications and performance criteria. This includes dimensional checks, material testing, and dynamic testing in simulated operating conditions.

Benefits of Partnering with Custom Camshafts Manufacturers

Companies looking to optimize their diesel engines can greatly benefit from collaborating with custom camshafts manufacturers:

Expertise and Knowledge

Manufacturers often employ teams of skilled engineers and technicians who have in-depth knowledge of diesel engine dynamics. Their expertise can lead to the development of innovative camshaft designs that push the limits of engine performance.

Customized Solutions

Every diesel engine operates under different conditions and requirements. Custom camshafts allow manufacturers to tailor their products to specific applications, ensuring compatibility and optimal performance.

Cost-Effective Options

Investing in high-quality, customized camshafts can lead to significant savings in the long run through improved efficiency and reduced wear and tear on engine components.

Industry Applications of Custom Camshafts

Custom camshafts can be utilized in various sectors, including:

- Transportation: Trucks and buses equipped with optimized camshafts can deliver greater payloads and better fuel economy.

- Agriculture: Agricultural machinery benefits from custom camshafts, enhancing performance during critical operational periods.

- Construction: Heavy construction equipment often relies on custom camshafts to ensure reliable performance under extreme loads.

- Marine: Diesel engines used in marine applications require tailored camshafts for optimal performance in varying water conditions.

The Future of Custom Camshafts in Diesel Engineering

The future for custom camshafts manufacturers looks promising as technology continues to advance. Here are several emerging trends influencing the industry:

1. Advanced Materials

Research into new materials that offer increased durability and lighter weights is ongoing. This might lead to even more effective camshaft designs.

2. 3D Printing Technology

3D printing is transforming manufacturing processes. While traditionally associated with prototyping, it's now being considered for producing custom camshafts, enabling rapid production and reduced waste.

3. Enhanced Simulation Software

As simulation software becomes more sophisticated, manufacturers can better predict how custom camshaft designs will perform, allowing for quicker and more effective iterations.

Choosing the Right Custom Camshafts Manufacturer

When selecting a custom camshafts manufacturer, consider the following factors:

- Experience: Look for manufacturers with a proven track record in diesel engine parts.

- Quality Certifications: Ensure they adhere to industry standards for quality (ISO certifications).

- Customization Capabilities: Evaluate their ability to provide tailored solutions.

- Customer Support: Strong after-sales support and service can enhance your partnership experience.

Conclusion

As the demand for efficient and high-performing diesel engines continues to increase, the role of custom camshafts manufacturers becomes ever more critical. By offering tailored solutions that enhance engine performance, efficiency, and longevity, these manufacturers are paving the way for innovations in the industry. Whether you're in transportation, agriculture, construction, or marine applications, partnering with a reliable manufacturer can significantly impact your performance and operational costs.

For those seeking to enhance their diesel engine performance, visiting sites such as client-diesel.com provides insight into potential partnerships with leading manufacturers of custom camshafts and diesel engine parts. As the market evolves, staying ahead with high-quality components will distinguish successful businesses from their competitors.